INTRODUCTION

Globalization has created a need for entrepreneurs to compete in order to sustain their firms (Fan, Li, & Wang, 2023). Undoubtedly, digital technology has significantly influenced the transformation of business models (Al-Somali, Saqr, Asiri, & Somali, 2024). Despite being a state-of-the-art concern, the integration of digital technology into a business process is not feasible without significant investment expenses, which are not inexpensive (Jabarivelisdeh, Jin, Christopher, & Masanet, 2024). The ultra-micro business sector is considered incapable of adopting digital technology (Anatan & Nur, 2023). An issue that requires addressed in the ultra-micro business sector is the lack of easily obtainable permissions from the local government (Anatan & Nur, 2023). The majority of unlicensed industries in Indonesia consist of a significant number of ultra-micro firms, with food and beverage businesses being the most prevalent. The ultra-micro food and beverage industry focuses on offering ready-to-eat food that is meant to be consumed immediately or stored only under frozen conditions (Mititelu et al., 2024). Entrepreneurs often experience this sentiment due to their failure to initiate the permission processing procedure.

In addition, ultra-micro entrepreneurs in the food and beverage sector face financial constraints, making it challenging for them to invest in digital technologies (Jabarivelisdeh et al., 2024). This is distinct from medium or large corporate conglomerates that already possess relatively substantial incomes to allocate towards digital technology, enabling them to undergo transformational measures aimed at reducing production costs and potentially even augmenting sales in order to attain disruptive profits. There is a significant disparity in income, particularly in terms of investment for digital transformation, between the ultra-micro business group and the medium-sized business group.

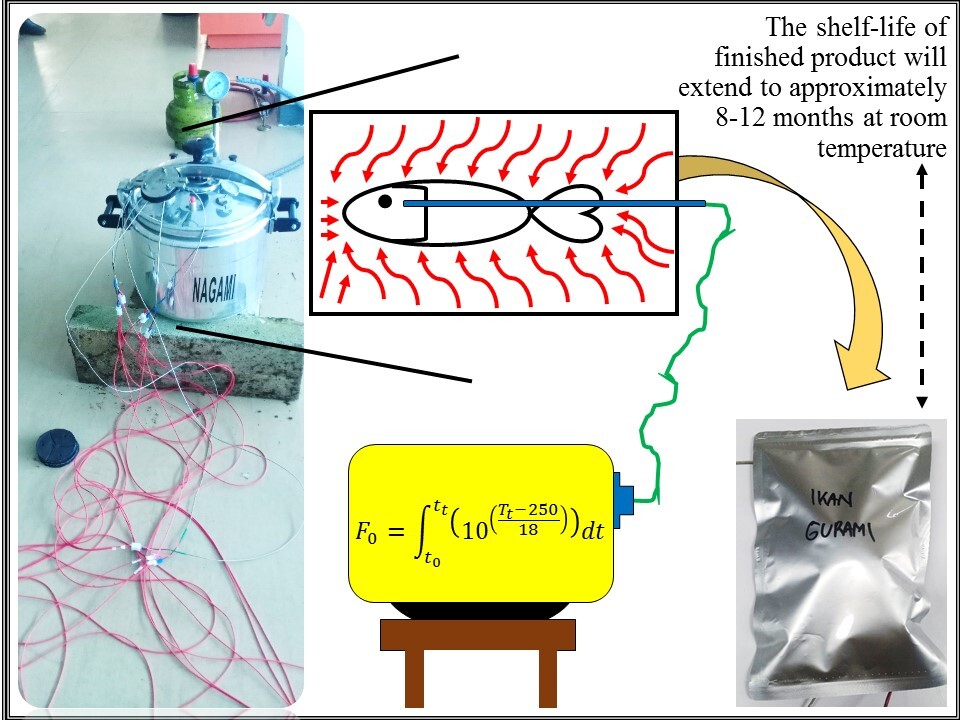

The digitalization goal for small-scale business collectives in the food and beverage industry can be initiated through the transformation of business operations and processes (Chen, Zhang, Jin, Wang, & Dai, 1920). The catering service industry, operating within the food and beverage sector, is an example of an ultra-micro group business that has the potential to revolutionize business operations and procedures. This industry specializes in providing on-call catering services to meet the meal requirements of households. Typically, these entrepreneurs also maintain a physical store to sustain their home finances, ensuring their survival even when there are no catering orders. The suggested business transformation involves transitioning from a traditional catering business or food stall to a packaged food enterprise that can endure extended periods without the need for refrigeration or freezing. This allows it to function as a food inventory that can be reprocessed when there is a demand for catering services (Tetteh et al., 2024). The suggested process transformation involves transitioning from regular cooking activities to utilizing commercial-grade sterilizing technologies for food processing. The catering services industry for households can expand its sales target location from individual households to include traditional markets, minimarkets, and supermarkets, so transforming its business and operations (Ziółkowska, 2021). The reason for this is that food product that have undergone commercial sterilization technology can remain viable for extended durations without the need for refrigeration or freezing, hence eliminating the expenses associated with post-processing handling (Diep et al., 2019). Commercial sterilization is the sole processing method capable of prolonging the shelf life of high-water and low-acid foods to over 1 year at room temperature (Diep et al., 2019). It is anticipated that the production capacity and business profits will augment. Commercial sterilizing technology presents a significant potential for ultra-micro entrepreneurs to enhance the sustainability of their enterprises and processes by embracing digital transformation.

This business and process transformation aims to enhance food security by processing food ingredients to extend their shelf life, particularly for perishable food ingredients (Cozzolino, Alagappan, & Hoffman, 2024). Perishable food product typically possess a high water and nutritional content (Gao et al., 2023). If food ingredients and processed foods with low acidity and high water content are not adequately handled after processing, they can serve as favorable environments for microbial development (Botlagunta & Babu, 2024). At present, commercial sterilization is the sole method that has been scientifically demonstrated to deactivate bacterial spores that are resistant to high temperature processes, therefore preventing spoiling (Munir et al., 2023). Clostridium botulinum is a spoilage bacteria that is specifically targeted for commercial sterilizing due to the high toxicity of its produced toxin (Glass et al., 2024). This has been enforced by the majority of governments worldwide, which states that low acid food sealed tightly and kept at room temperature must undergo commercial sterilization. That process should achieve at least 3.0 minutes when measured against Clostridium botulinum spores (Hariyadi, 2019). According to the law, food products or processed foods that are considered high risk due to their low acid content and high water content, and are intended to be maintained at room temperature in sealed packaging, must undergo commercial sterilization (Chiozzi, Agriopoulou, & Varzakas, 2022).

The necessary benchmark for commercial sterilization is the eradication of Clostridium botulinum spores, which requires a minimum F0 value of 3.0 minutes (Singh & Ramaswamy, 2023). This information may be challenging for individuals involved in ultra-micro businesses who may lack the necessary knowledge to comprehend the technical aspects of commercial sterilizing. This method effectively achieves a 12 log cycle reduction in the inactivation of Clostridium botulinum spores. It does so by transferring heat from a hot medium to the most challenging area in food that is difficult to access by heat, even when the food is in an unsteady state. Undoubtedly, they possess a range of processed foods with low acidity and high water content. However, owing to scientific constraints, these processed foods are manufactured in the frozen form (Liu et al., 2023). The frozen storage is a challenge because to the restricted facilities available for the distribution process, namely the requirement for the condition to be maintained as frozen during transportation. This challenge can be effectively addressed by utilizing cryogenic containers. However, the primary obstacle lies in the necessity of distributing substantial quantities or distributing in bulk (Ren, Ren, Matellini, & Ouyang, 2022). Large-scale distribution typically employs oversized vehicles, however limited infrastructure in remote areas of Indonesia might result in product deterioration during transportation without the use of refrigeration equipment (Lorenc, 2024). Commercial sterilizing has significant potential for use due to the high cost of distributing utilizing frozen containers.

Currently, the sole choice for sterilizing food and beverages in containers for commercial purposes is to utilize a retort device (Lee & Shin, 2023). Nevertheless, it is important to acknowledge that engaging in retorting necessitates substantial financial expenditure for small-scale business operators. While certain enterprises may have the financial means to invest in retorts, there is another significant expense that they must also consider: the cost of verifying the effectiveness of the sterilization procedure. Several agencies conducting assessments on the effectiveness of commercial sterilizing techniques, which are typically relied upon for their dependability in testing, have established significantly elevated standards. Indeed, while dealing with various food components, it is imperative to reassess the effectiveness of sterilization. In addition, when employing an alternative or novel retort instrument, it is necessary to assess the effectiveness of the re-sterilization procedure. Given the significant quantity of products requiring sterilization and the frequent changes in equipment, the demand for testing the sterilization process will inevitably rise. The expenses associated with testing will inevitably multiply significantly due to these two considerations (Pursito, Purnomo, Fardiaz, & Hariyadi, 2020). The expense is undeniably burdensome for ultra-micro entrepreneurs that are establishing a food service company in the form of basic catering, offering a diverse domestic menu that is designed for immediate consumption.

A cost-effective approach to address the expensive investment costs associated with retorts and the testing expenses for ensuring the effectiveness of the sterilization process for various food products is to utilize a modified domestic pressure cooker (Swenson et al., 2018). Modifications to the pressure cooker involve adding a hole in the lid specifically for the thermocouple connection. A thermocouple is required in the pressure cooker to measure both the temperature of the pressure cooker itself and the temperature at the lowest point of the product throughout its operation. The thermocouple was selected due to its ability to provide real-time temperature readings, unlike temperature data recorders which lack this capability. Thermocouples have lower investment costs compared to data recorders. This solution enables a commercial sterilization process that is regulated and supervised to promptly assess the effectiveness of the sterilization process, even when applied to various products. This is achieved by placing a thermocouple on one of the products at the coldest point of the apparatus during the sterilization process, as part of the heat distribution test. The objective of this study is to assess the thermal distribution characteristics of pressure cookers and evaluate the effectiveness of the sterilization procedure for various food products in the food service sector.

MATERIALS AND METHODS

Materials

The materials utilized in this study consisted of milkfish, squid, grilled chicken, rendang, chicken satay, retort bags, and iron glue. The necessary equipment includes a Rex C100 PID Thermostat, a single fiber cable, a heat resistant cable, cable connectors, sockets, cable skuns, a K type thermocouple with a spade type connector, a 25 Liter Nagami brand pressure cooker, a stainless steel net for the pressure basket cooker, a gas stove, a furnace, a gas hose and regulator, a gas cylinder, a rubber pressure cooker hole cover, and a stainless steel plate.

Measurement of Heat Distribution in a Pressure Cooker

The heat distribution test is conducted just once for a certain product (Yudianto, Dewanti-Hariyadi, Sukarno, Nur, & Purnomo, 2023). However, in this experiment, five heat distribution tests will be performed on samples of milkfish, squid, grilled chicken, rendang, and chicken satay. Evaluate the thermal dispersion by conducting experiments on a domestic pressure cooker with a volume of 25 liters. A hole is added to the pressure cooker lid to accommodate the thermocouple cable. The pressure cooker basket is organized with ordinary samples and packages without samples, the latter of which are equipped with a thermocouple. The packing without samples that have been given a thermocouple are positioned in a spread-out manner at the bottom, edge, middle, and top of the basket. The water is heated within a pressure cooker until it reaches its boiling point. Next, the basket containing the sample and packing, together with the thermocouple, is immersed in boiling water within the pressure cooker. The pressure cooker lid is securely fastened, with the steam weight removed to allow for venting. At this point, the temperature is measured using the thermostat. Once the water vapor reaches a stable state, the ballast is sealed and the time it takes to release the vapor is recorded. The heating operation is continued until the temperature recorded on the thermostat monitor remains constant for a duration of at least 30 minutes. Subsequently, the process of heating is halted.

Validation of Sterilization Process

The sterilization technique involves utilizing a household pressure cooker with a 25-liter capacity, as demonstrated in the heat distribution test. The pressure cooker basket is organized with both regular samples and samples equipped with thermocouples. The thermocouple-equipped samples are strategically positioned at the bottom, edge, middle, and top of the basket. This treatment is administered singularly at the onset to validate the heat distribution outcomes of the preceding pressure cooker. Only one product is equipped with a thermocouple in the coldest area of the confirmed pressure cooker for all future procedures. This ensures continuous monitoring and validation of the commercial sterilizing process. The sterilizing process is conducted using the same method as the heat distribution test for a pressure cooker.

General Method

In order to obtain the F0 value in real-time, one can immediately input the formula for computing the F0 value into Microsoft Excel. Each time there is a fluctuation in temperature over a given time period, it will be directly recorded in Microsoft Excel, enabling the automatic calculation of the F0 value. The attainment of an F0 value of 3.0 minutes will indicate the successful completion of the commercial sterilizing process. Typically, the duration of the operation is extended by a factor of 2 to 3 in order to account for any unforeseen cold spots in the pressure cooker. The sterilization procedure involves the complete inactivation of Clostridium botulinum spores by subjecting them to a standard inactivation of 12 log cycles at a reference temperature of 121.1°C (Yudianto, Dewanti-Hariyadi, Sukarno, Nur, & Purnomo, 2023). The formula for assessing the effectiveness of the sterilization procedure is determined by the Z value, which is set at 10°C (Jung, Lee, & Yoon, 2023). That equation was based on the integration between the need of 12 log cycles of Clostridium botulinum spores and first order kinetic model for bacteria inactivation by thermal process.

Processing time for sterilization process is commonly known by F.

the first order kinetic model follows (Sun, Xu, Wu, Shen, & Zhan, 2023):

k(N) = -

Back to -->

T is temperature (°F). N is total bacteria (CFU/mL). D is time to change 1 log cycle of bacteria inactivation (minute). Z is the temperature change for 1 log cycle of D value change (°F).

Ball Formula Method

To predict temperature fluctuations in the pressure cooker caused by unforeseen circumstances, it is necessary to conduct a scheduled sterilization process adequacy test. The scheduled process is determined by the temperature and duration of the sterilization process in a pressure cooker. This is calculated using various variables in the ball formula to achieve a specific sterilization value. Therefore, if the temperature of the pressure cooker changes, it only needs to determine the corresponding duration for the sterilization process under the new conditions (Praharasti et al., 2020). The current temperature of the pressure cooker in operation. In order to ascertain the variables in the ball formula, it is imperative to plot the heat distribution in the sterilized material by employing the subsequent unstable heat transfer equation (Hariyadi, 2019):

The K value will be similiar for a similiar product, size, and packaging. By graphing the temperature change data for each change in heating time using either the exponential or linear model mentioned before, we may determine various variables in Table 1, specifically:

Table 1

The Ball Formula Method Variables.

By utilizing the thirteen variables mentioned, it is possible to determine the specific combination of temperature and processing time for sterilization in a pressure cooker. This combination will result in a desired F0 value, based on the interaction of these variables. The F0 value calculation using the Ball formula method is determined based on the lowest F0 value obtained from one of the thermocouples, which measures heat penetration, in the general method. It is hypothesized that if the lowest F0 value can produce a satisfactory model and be utilized, then all thermocouples that generate F0 values in the general method will also yield satisfactory models and be usable.

RESULTS AND DISCUSSION

Measurement of Heat Distribution and Products in Pressure Cookers

Figure 2 displays temperature data of pressure cookers and various products used in the food service business. The assessed goods were milkfish, squid, grilled chicken, rendang, and chicken satay. Figure 1 displays various products as samples including rendang, grilled chicken, milkfish, chicken satay, and squid, respectively. The domestic pressure cooker utilized ensured consistent heat distribution, maintaining a temperature range of 246.2°F during the testing of the five different products. The sterilizing process in the household pressure cooker is depicted in Figure 1G. The coolest side of the milkfish, squid, grilled chicken, rendang, and satay product can reach maximum temperatures of 235.4, 242.6, 233.6, 235.4, and 221°F, respectively. The thermal conductivity of the packing material is also a determining element in its ability to transfer heat to the coldest side of the product. Figure 1F illustrates that the packaging employed is a retort pouch, which facilitates the transfer of heat from the external environment to the coldest part of the product. It could transfer the heat well (Fardella et al., 2021).

Upon examining Figure 2, it becomes evident that all goods, with the exception of chicken satay, are subjected to heat that is nearly identical to the temperature of a pressure cooker. The monitored temperatures of chicken satay products typically do not exceed 212°F, however they may temporarily surpass this threshold for a brief period. Nevertheless, the outcome of this heat penetration will directly impact the attainment of the F0 level. If the temperature at the coldest point of the product cannot exceed 212°F within a specific duration, the reference temperature of 250°F must be taken into account. This difference is important in determining a F0.

F0 Value by General Method

Figure 3 displays the outcomes of the calculation of cumulative F0 variations over time. The chart illustrates that four goods, specifically milkfish, squid, grilled chicken, and rendang, have exceeded the permissible commercial sterilizing criteria in terms of their cumulative F0 values. The duration is 3.00 minutes. Based on the statistics provided, it is evident that all four goods have successfully undergone commercial sterilizing. In contrast to the other goods, the chicken satay products failed to achieve a cumulative F0 value of 3.00 minutes. This outcome is predictable based on the information shown in Figure 2, which indicates that chicken satay products are unable to tolerate temperatures below 212°F for an extended duration.

By monitoring real-time temperature changes, the sterilization process may be tested for effectiveness. This allows for the determination of the final F0 value, which is displayed in Table 2. Every product, except for chicken satay, has undergone commercial sterilization based on the entire process duration (B value) at a relative operating temperature of 246.2°F in the pressure cooker. Due to the low temperature experienced by chicken satay products at their coldest point, it is not possible for them to achieve commercial sterility within 1-3 hours of processing. Due to the excessive duration required for commercial sterilization of chicken satay product, it is no longer essential to determine the F0 value for this particular product.

F0 Value by Ball Formula Method

By attaining commercial sterilization for milkfish, squid, grilled chicken, and rendang goods, it becomes possible to determine the F0 values of these four products using the Ball formula approach. Calculating the F0 value using the Ball formula approach is not feasible for chicken satay products due to the fact that the general method has not yet attained commercial sterilization. In order to calculate the F0 value using the Ball formula approach, it is necessary to have the results of calculating the F0 value using the general method. This is necessary to verify the usability of the variables Fh and jI in the Ball formula method.

Figure 4

Graph Depicting the Relationship between Temperature (Tr) and Time in The Heat Penetration of Milkfish.

Figure 5

Graph Depicting the Relationship between Temperature (Tr) and Time in The Process of Heat Penetration in Squid.

The milkfish products have known Fh and jI values, as shown in Figure 4. Upon examining Table 3, it becomes evident that the F0 value obtained using the Ball formula approach is higher than the F0 value obtained using the general method. Figure 4 becomes invalid due to the inability to utilize the Fh and jI variables in plotting the difference in pressure cooker temperature and product temperature against process time. This occurs due to the inadequate visibility of the linear heat penetration graph within the product.

Figure 6

Graph Depicting the Relationship between Temperature (Tr) and Time in The Heat Penetration Process of Grilled Chicken..

The slow heat conduction from the tool to the coldest part of the product often affects the visibility of linear sections. The sluggish heat penetration can be affected by the slow rate at which the heating/sterilization device reaches temperatures that are similar to the standard commercial sterilization temperature, specifically 250°F. In addition to the tool's characteristics, the product itself also influences the speed at which heat is able to penetrate. Products with a high water content, such as gravy, typically possess favorable heat penetration qualities. Conversely, if the product has little moisture content, it will impede the transfer of heat into the product (Mahir, Maakoul, Khay, Saadeddine, & Bakhouya, 2021). The presence of oil in food also enhance the heat transfer in that product (Hoffmann et al., 2016).

Despite the poor rate of heat penetration, commercial sterilizing can still be accomplished for milkfish products by extending the processing time. A similar occurrence is observed with grilled chicken product as well. Grilled chicken product have undergone commercial sterilizing. Nevertheless, the F0 calculation findings obtained using the Ball formula approach are identical to those for milkfish products. Specifically, the F0 value obtained using the Ball formula method is greater than the F0 value obtained using the general method. Based on the outcomes of these computations, it is not now possible to utilize the variables Fh and jI depicted in Figure 6 .

Figure 7

Graph Illustrating the Relationship between Temperature (Tr) and Time in The Process of Rendang Heat Penetration..

When the squid product is heated, a fractured linear section becomes visible. The fractured segment is affected by the nature of the squid, which undergoes solidification when exposed to heat. The squid's texture undergoes a process of hardening, which results in alterations in the speed at which heat is absorbed. The thermal conductivity of the tender squid is high, resulting in a rapid rate of heat transfer as indicated by the steep incline of the first heating curve. As the squid's texture solidifies, the rate at which heat is absorbed slows down, as seen by the gradual slope of the heat penetration curve shown in Figure 2. Figure 5 illustrates the process of determining the Ball formula variable for calculating the F0 value using a broken curve. In addition to Fh and jI, the broken curve contains two extra variables, F2 and Xbh, which arise from the intersection of the linear lines in the two broken linear sections. Upon doing the calculations outlined in Table 4, it is evident that the value of F0 obtained through the Ball formula approach surpasses the value obtained through the general method. Consequently, the variables Fh, jI, F2, and Xbh depicted in Figure 5 are deemed unsuitable for usage.

The variables in the Ball formula for calculating outcomes for milkfish, grilled chicken, and squid product are currently not applicable for scheduled process calculations. Based on these findings, it is advisable to maintain the three product in a sterilized state at the exact same temperature settings as during the sufficiency test of the sterilization process. Essentially, the planned process aims to observe and predict the B and Pt values as they approach a specific F0 value in response to abrupt fluctuations in temperature. The inability to ascertain F0 using the Ball formula does not imply the failure of commercial sterilization, as the Ball formula is a theoretical framework that requires confirmation for its application.

Table 3

Validation of the Ball Formula Model for Milkfish, Grilled Chicken, and Rendang Products.

Table 4

Validation of Ball Formula Model for Squid Products.

Table 3 demonstrates that theF0 values obtained using the Ball formula technique are lower than those obtained through the standard method for rendang. Therefore, the variables Fh and jI depicted in Figure 7 can be utilized to compute scheduled processes. The validation of the Fh and jI variables is performed by comparing the F0 value using the Ball formula method with the values obtained from the Ball formula and general methods. If the computed value of F0 using the Ball formula approach is less than F0 using the general method, variables can be employed. This comparison suggests that if the F0 value obtained using the Ball formula approach is approximately 3.00, then the original F0 value must be satisfactory, as it exceeds the Ball formula method and will be significantly larger than 3.00. If the calculated value of F0 using the Ball formula approach exceeds the value of F0 obtained using the general method, there is a difference. This situation poses a significant risk, as an F0 number that is in close proximity to 3.00 when utilizing the Ball formula approach indicates that the initial F0 value may be less than 3.00, hence failing to achieve commercial sterilization.

Table 5

Calculation of Scheduled Processes for Rendang.

Table 6

Summary of Scheduled Processes for Rendang Products at Different Temperature Values, F0, B, and Pt.

Schedule Processes

The calculations for the scheduled process of rendang are presented in Table 5. Accurate process calculations necessitate the utilization of a consistent value for j. The constant j remains constant as long as the product and packaging conditions remain the same as during the sterilizing adequacy test. Once the constant j is acquired, the values of B and Pt can be calculated based on the desired F0 value for alternative changes in process temperature. This computation involves determining the inverse of the calculation used to find the value of F0, which is already known for the given values of B and Pt. Table 6 provides a concise overview of the planned procedure for sterilizing rendang using a pressure cooker commonly seen in households. There are nine distinct variations in process temperature that serve as benchmarks for the sterilization process. These variations account for the potential changes in temperature that may occur due to a decrease in equipment performance. There are nine temperature variation options available, and each option provides information on the B and Pt values required to produce the estimated F0 value.

Typically, products that have performed commercial sterilizing processes can be stored at room temperature for over a year without deterioration (Xue et al., 2023). This one-year guarantee is based on the principle of 12 log cycle inactivation of Clostridium botulinum spores, hermetic packaging, and a low level of chemical deterioration in quality. The 12-log cycle inactivation of Clostridium botulinum spores can be considered an opportune. During a single batch of commercial sterility food production, there is a one in one billion chance that one product may get infected with Clostridium botulinum spores, provided the initial bacteria 1000. These findings suggest that when the quantity of commercially sterilized food products manufactured is limited to 10,000 units, the likelihood of contamination by Clostridium botulinum spores is 0.00001 spores. This situation implies that there is a significant likelihood of sterility in all manufactured products.

Following the sterilization procedure, it is enclosed in hermetic packaging. Hermetic packaging refers to a type of packaging that is completely sealed, preventing any exchange of air between the inside and exterior of the package (Borém et al., 2021). This will preserve the sterility of products that have undergone commercial sterilizing processes, ensuring a minimal risk of microbiological contamination, particularly from Clostridium botulinum spores. Once the threat posed by bacteria is successfully mitigated, the duration for which the product remains suitable for consumption will no longer be influenced by microbial activity, but rather by the activity of chemical constituents present in the food. Under optimal food storage conditions, the rate of food decay is typically low, resulting in a significantly prolonged time for food to spoil due to the chemical processes occurring within it (Afriyie et al., 2022). Commercial sterility of food products typically exhibit a prolonged shelf life at ambient temperature, often exceeding one year.

The commercial sterility in this research was carried out by a thermal process. Several advantages of this commercial sterility process include extended shelf-life at ambient temperature; eliminating the need for refrigeration or freezing for food storage; the product can be easily handled and supplied at any time and location. However, the disadvantages of the commercial sterility process include the requirement for expensive steam production; the unsuitability of certain products for this process; the potential destruction of products due to high temperature and pressure process; and the limitation on product size imposed by packaging volume (Pursito et al., 2020).

CONCLUSION

Food service business menus containing milkfish, squid, grilled chicken, and rendang can be effectively sterilized using a residential pressure cooker. The utilization of variables in the flawed curve for squid goods is incapable of generating a F0 value using the Ball formula approach, which is inferior to the general method. The variables in the Ball formula for rendang products can be utilized to calculate scheduled process conditions. Nine scheduled process conditions have been calculated for the commercial sterilization process of rendang as a contingency in case there is a variation in the temperature of the pressure cooker.

Author contributions

AS – Collected the data; AS, DY - Performed the analysis; AS - wrote the manuscript with support from FS, MFM, DY; AS, DY - Conceived and designed the analysis; FS - supervised the project; MFM - helped supervise the project; DY - Analysis tools and Thermal Process Engineering Designer.